KANOPEO Bifurcation SAFEROLLER Bulletin

From KANOPEO (PDF directly from KANOPEO):

At KANOPEO, safety is our number one priority.

Since 06.03.2019, KANOPEO has been ISO 9001:2015 certified.

This certification has allowed us to improve our development, production, control, information and monitoring processes.

These technical bulletins allow you to easily access information produced by KANOPEO. It is always accompanied by detailed technical support.

WHO IS CONCERNED?

Park operators and managers.

Technicians responsible for the inspection and maintenance of PPE in an AHA

(Adventure High Ropes Park).

SAFEROLLER®

X Lifeline PPE* ACCESSORIES *PPE: Personal Protective Equipment

PRIORITY LEVEL

Actions that need to be taken 1 Critical security. Must be corrected immediately. Stop usage until

inspection/modification2 Must be corrected as soon as possible X 3 No immediate danger, but requires special attention or monitoring; potential

long-term risk4 KANOPEO recommendation for improvement 5 Information Retroactive application ? *

Yes X No *A retroaction application requires the installation to comply with the latest version of the

manual.

SUBJECT:

Following feedback from a park builder and parks operator, it has been reported that pulley exit

forcing at the bifurcation may occur under specific conditions.

Taking our clients' feedback seriously and proactively, we are sharing here the inspection and

correction measures.This complements KANOPEO technical manuals available on JDOC.com:

10. SAFEROLLER 2 ASSEMBLY CBS HANDBOOK 2025 V4.6

21. SAFEROLLER PPE TROLLEY TYPE 3 2025 V3.6

20. SAFEROLLER PPE TROLLEY TYPE 2 2020PRODUCTS CONCERNED

SAFEROLLER BIFURCATIONS

- SR2 – BIFURCATION RIGHT – SAFE0300413

- SR2 – BIFURCATION LEFT – SAFE0300414

PULLEYS

All pulleys used in conjunction with bifurcations.PROCEDURE

What:

- Identify potential wear on SAFEROLLER bifurcations.

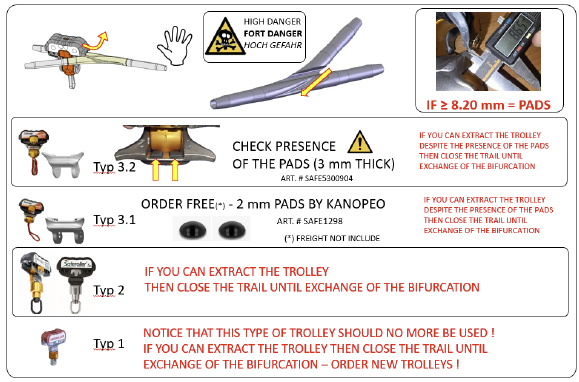

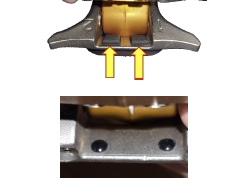

- Check for the presence of pads on pulleys of version type #3.2.

- Assess the risk of pulley exit, regardless of version.

What are we looking for?

Avoiding the risk of unintended SAFEROLLER pulley exit during manipulation at the bifurcation.How:

Inspect the pulley groove width.

If the groove width exceeds 8.20 mm,

then pads must be installed.

Important:

If you still wish to perform an extraction test, do not forget to be securely attached to the lifeline by a means other than the pulley you are testing!Installing the closing stops does not necessarily reduce the groove width below 8.20 mm, but unless the bifurcation is significantly worn, it should prevent pulley exit.

Regularly check for the presence of the pads.

Install the pads approx. 2 mm below the edge of

the closure. Clean with acetone before installation.

In case of doubt:

Contact the KANOPEO team with a photo illustration.

Send an email to: info@kanopeo.com